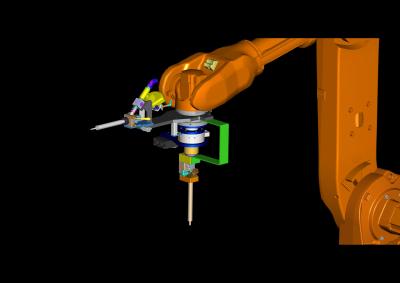

Servotak provides a comprehensive range of robust and high precision gearboxes for the robotic industry

High precision Servotak gearboxes position ship crankshafts during machining in horizontal lathes. Servotak gearboxes offer a robust and efficient solution to machine tools, providing high precision to the axis, and offering an extraordinary versatility, thus greatly increasing our customer's productivity. The highly modular design of the gearboxes enables a high degree of adaptation to individual needs, with high efficiency and accuracy.

Servotak high precision gearboxes are a perfect match for food processing and packaging machines, in applications such as:

- cutting equal weight tuna slices.

- positioning cans of tuna for packaging at high speed with high accuracy.

- placing exact quantities of chocolate at precise locations.

- making sure that each bum is correctly placed prior to wrapping.

Their low backlash, leading to extremely accurate positioning, allow a substantial increase in pick and place robot productivity.

Servotak gearboxes are also present in the renewable energies industry. Photo-voltaic power stations use high precision solar trackers to ensure an optimal incidence angle, for maximum power generation. High performance multipliers are used to harness marine current power, transmitting the motion to electrical generators. Servotak gearboxes are also used in the quenching of large gear wheels, for use in wind turbines.

Substantial savings, due to more efficient and precise motion, can be obtained in factories, by employing appropriate high precision Servotak gearboxes in machinery and manufacturing equipment.

High precision positioning is also fundamental for surveillance systems, used in airports, hazardous locations, high capacity stadiums and forest surveillance systems.

The automotive industry uses Servotak gearboxes in assembly lines, for precision turning of car bodies, sub-assemblies, and parts, so as to have them assembled and welded by the robots. Most automobiles include transmissions that were manufactured by machines that included Servotak gearboxes to meet the most stringent quality controls.

Aerospace industries have many needs filled by Servotak high precision gearboxes. For example, Servotak gearboxes were employed in the world's largest radio interferometer, an array of 64 parabolic dishes, equivalent to a single 14 km diameter radio-telescope capable to make measurements of the early history of the universe. We're proud to have been part of this project, born of the collaboration between the NAOJ (National Astronomical Observatory of Japan), the NRAO (National Radio Astronomy Observatory, USA), and the ESO (European Southern Observatory).

Servotak is able to provide a broad range of customization for existing models, and of custom-made gearboxes, thanks to our open-mindedness and our constant search for improvement.